Implementing Year Make Model (YMM) Modules: Challenges and Solutions

Shopping online for car parts as a consumer is just so darn easy.

All a shopper needs to do is select the year, make, and model (YMM) of their vehicle in a handy module, select a few more specific options (trim, engine, etc.), and boom – they’re treated to a curated selection of parts designed for their car. Get the selections right, and consumers will keep returning; get it wrong, and you’ll have to deal with product returns and, more importantly, unhappy customers.

This seemingly magic simplicity on the front end of a website or application is shrouded by incredibly complex data parsing on the back end. Integration challenges include everything from managing vast amounts of bespoke data to integrating YMM modules with existing systems.

Let’s cover the most pressing challenges for integrating effective YMM modules and solutions that make sense for your business.

Where Does YMM Data Come From?

YMM data is typically aggregated from a variety of sources:

- OEM Sources (Original Equipment Manufacturers): OEMs are a primary source of YMM data. This data is based on the original specifications and fitment information provided by the vehicle manufacturers themselves, ensuring that the information is accurate and directly tied to the vehicles for which the parts were designed.

- Aftermarket Parts Manufacturers: In addition to OEMs, aftermarket manufacturers provide YMM data to make sure that their parts, which are often alternatives to OEM parts, are accurately matched to the appropriate vehicles. This data is critical for businesses that sell aftermarket parts, as it helps make sure that customers can find the right non-OEM options for their vehicles.

- Third-Party Data Providers: These providers aggregate and standardize data from multiple sources, including OEMs and aftermarket manufacturers. Third-party providers often format this data according to industry standards, such as ACES (Aftermarket Catalog Exchange Standard) and PIES (Product Information Exchange Standard), making it easier for businesses to integrate the data into their systems.

How Do YMM Modules Work?

YMM modules operate by organizing vehicle fitment data in a structured way, typically following industry standards such as ACES and PIES.

Here’s a breakdown of the process:

- Data Structuring:

YMM modules rely on structured data to match parts and accessories with specific vehicles. This data includes detailed information about the vehicle’s year, make, model, and sometimes additional details like sub-model or trim. Each product in the catalog is associated with the vehicles it fits based on this data. - User Interaction:

When a customer visits an eCommerce site, YMM modules power the search filters that allow them to input their vehicle’s details. The customer selects their vehicle’s year, make, and model, and the YMM module filters the available products to show only those that are compatible with the selected vehicle. - Fitment Matching:

Behind the scenes, the YMM module checks the fitment data to ensure that the parts being shown are correct for the vehicle. This reduces the chances of customers purchasing the wrong parts, which can lead to dissatisfaction and returns. - Integration with Product Catalogs:

YMM modules are integrated with product catalogs and inventory systems. This integration ensures that the products listed as compatible with a specific vehicle are available in stock and ready to ship. The modules also update automatically as new parts become available or when new vehicle models are added. - Support for Advanced Features:

Advanced YMM modules can handle more complex requirements, such as managing bundles (e.g., a brake kit that includes multiple components) or dealing with regional variations in vehicle specifications. These features ensure that even more specialized products can be accurately matched to the right vehicles. - Continuous Updates:

As vehicle models evolve and new data becomes available, YMM modules need to be continuously updated. This is often done through regular data imports from OEMs, aftermarket manufacturers, or third-party data providers. Automated updates ensure that the YMM module remains accurate and up-to-date, reflecting the latest product and vehicle information.

How Does a PIM System Work with YMM Modules?

When combined with Year/Make/Model (YMM) modules, a PIM system becomes even more powerful for automotive businesses, allowing them to manage both product information and fitment data seamlessly.

Here’s how they work together:

Centralized Data Management

A PIM system centralizes all product data, including descriptions, images, specifications, and pricing. When integrated with YMM modules, it also houses detailed fitment data that links products to specific vehicles.

- YMM Data Integration:

The PIM imports YMM data from sources like OEMs and third-party providers, linking it to the corresponding products. Regular updates ensure that vehicle compatibility information is always current, reducing the risk of mismatches and returns.

Improved Data Consistency Across Channels

A PIM system ensures consistent product and fitment data across all sales channels, reducing errors and improving customer trust.

- Channel-Specific Data Distribution:

The PIM system distributes consistent data to eCommerce platforms, marketplaces, and physical stores, ensuring that the correct vehicle fitment data is attached to each product listing. - Reduced Errors:

By centralizing product and YMM data, the PIM reduces errors that can occur when manually updating multiple systems.

Enhanced Search and Filtering Capabilities

YMM modules enable customers to find the right parts for their vehicles. Integrated with a PIM, this capability is enhanced for better search functionality.

- Advanced Filtering Options:

The PIM uses YMM data to power vehicle-based filtering, allowing customers to enter their vehicle’s details and see only compatible products. - Improved Product Discovery:

Combining detailed product information with accurate fitment data helps customers discover relevant products, leading to increased sales and confidence in their purchase decisions.

Scalability and Automation

A PIM system integrated with YMM modules helps businesses scale by automating data management.

- Scalable Data Management:

PIM systems handle large volumes of data, making them ideal for businesses with expansive catalogs and complex YMM requirements. - Automation of Routine Tasks:

Automating updates, validation, and data distribution reduces manual effort, ensuring that data remains accurate as the business grows.

Enhanced Reporting and Insights

A PIM system provides insights into product performance and fitment accuracy, helping businesses make informed decisions.

- Performance Tracking:

By analyzing product performance across vehicle segments, businesses can adjust their offerings to meet customer demand. - Fitment Accuracy Analysis:

The PIM system can track fitment accuracy by analyzing return rates, allowing businesses to improve data and reduce future returns.

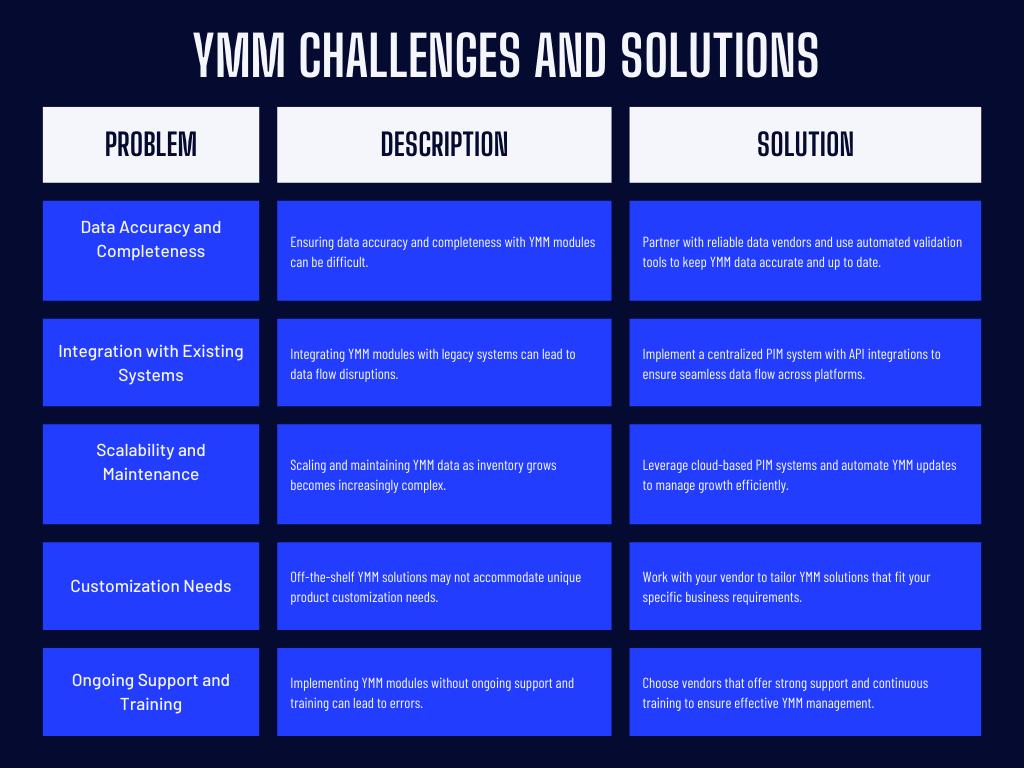

Challenges and Solutions: Breaking It Down

Challenge 1: Data Accuracy and Completeness

The Challenge:

One of the most significant challenges businesses face when implementing YMM modules is sourcing accurate, up-to-date data. Incomplete or inconsistent YMM data can lead to product incompatibility, customer dissatisfaction, and an increase in product returns. This not only affects the customer experience but can also result in lost sales and damage to your brand’s reputation.

The Solution:

Investing in reliable data vendors that specialize in automotive data is crucial.

By partnering with vendors who have expertise in the industry, you can ensure that your YMM data is accurate, comprehensive, and regularly updated. Additionally, utilizing automated data validation tools can help continuously audit and update your YMM data, minimizing the risk of errors and outdated information.

These tools streamline the data management process, reducing manual effort and ensuring that your data remains consistent across all channels.

Challenge 2: Integration with Existing Systems

The Challenge:

Integrating YMM modules with existing legacy systems can be complex and disruptive. Businesses often struggle with data flow issues, system performance challenges, and inconsistencies when handling multiple platforms. Manual data entry across disconnected systems creates opportunities for errors and inefficiencies, which can slow down operations and affect the accuracy of fitment information.

The Solution:

To overcome this challenge, implementing a centralized Product Information Management (PIM) system is key.

A PIM system that integrates with ACES and PIES standards allows seamless data flow across all platforms, reducing the need for manual data entry and ensuring that your fitment data is consistent and accurate. API integrations are also essential for connecting YMM modules to your existing systems, enabling real-time data synchronization and minimizing disruptions during implementation.

Challenge 3: Scalability and Maintenance

The Challenge:

As your inventory grows, maintaining YMM data becomes increasingly complex. Scalability becomes a significant concern, as larger inventories require more resources to manage data, ensure accuracy, and prevent system performance issues. Without proper planning, scaling YMM modules while maintaining ongoing accuracy can quickly overwhelm your team and system.

The Solution:

Leveraging cloud-based PIM systems offers a scalable solution that doesn’t compromise performance. Cloud-based systems allow for flexibility as your business grows, ensuring that your YMM data can be managed efficiently even as your inventory expands. Automating YMM data updates is another critical step in handling scalability. Regularly scheduled audits and data cleaning can help prevent issues as your inventory grows, ensuring that your data remains accurate and up to date.

Challenge 4: Customization Needs

The Challenge:

Many automotive businesses have unique needs that off-the-shelf YMM solutions can’t address. For example, handling specialized inventory, bundles, or specific product types may require custom YMM solutions. Off-the-shelf systems may not provide the flexibility needed to address these nuances, leading to inefficient workarounds that slow down operations.

The Solution:

The key to solving this challenge is working closely with your data vendor or PIM provider to develop tailored YMM solutions that meet your specific business requirements. Customization should be built into your system to accommodate the unique aspects of your inventory, whether that means handling bundles, specialty products, or other configurations.

Ensure that your system is flexible enough to adapt to future changes, allowing for scalability and easy updates as your business evolves.

Challenge 5: Ongoing Support and Training

The Challenge:

Implementing YMM modules can be complex, and without ongoing support, businesses may struggle with system management and troubleshooting. Additionally, without proper training, staff may make errors in data entry, system usage, and overall YMM management, which can affect the accuracy of your data and the performance of your system.

The Solution:

To address these issues, partnering with vendors that offer robust support and ongoing training is essential. Choose vendors who provide accessible resources and assistance to help your team navigate any challenges that arise during and after implementation. Investing in regular training sessions for your staff, particularly when new features or system updates are introduced, ensures that your team remains proficient in using the system.

By prioritizing ongoing education and support, you can reduce the likelihood of errors and keep your YMM modules running smoothly.

Ready To Implement Effective YMM Tools?

Implementing a PIM system integrated with YMM modules is a game-changer for automotive businesses, ensuring accurate fitment data, streamlined operations, and improved customer satisfaction. If you’re ready to take your product management to the next level, we’re here to help!

Ready to Make Ymm tools Work For You?

Get started with SureDone – the ultimate solution for managing YMM data effortlessly. Contact our sales team now or schedule your demo to unlock the full potential of your business with SureDone.